Foto: https://www.magway.com

The rapid growth of e-commerce over the past 10-15 years has had a dramatic impact on urban traffic and the environment. Trucks delivering goods are leading to ever increasing emissions. The volume of global deliveries is expected to grow to 200 billion packages by 2025.

On one hand, this reflects a new era in customer service, while on the other hand, it draws attention to the problem of emissions. The World Economic Forum projects a 30% increase in emissions in the 100 largest cities on the planet by 2030. But what if there was a way to eliminate those emissions and take this congestion off the streets?

This is what Magway aims to achieve with a revolutionary solution in which steel plays a crucial role. This approach can help significantly improve the sustainability of delivering goods in megacities.

More Than Just a Dream

The Magway system aims to provide a safer, faster, more reliable and more sustainable way of delivering packages than current solutions.

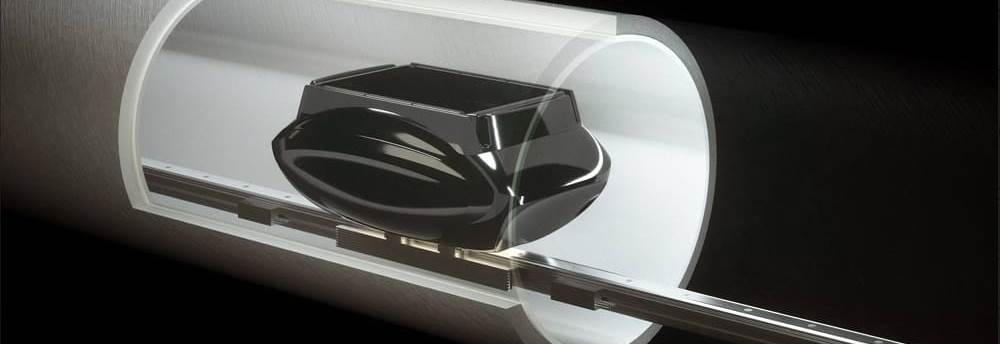

Using an electromagnetic motor system to drive carts along steel tracks, Magway takes traffic off the streets and puts it into pipes.

Co-Founder and Commercial Director of Magway Phill Davies says: "Magway is a solution for addressing the explosive growth of online deliveries and the resulting volume of goods that have been transported by polluting vehicles. We remove trucks from roads to ease traffic and deliver goods via pipes in a safe and environmentally friendly way."

Foto: https://www.magway.com

Davies co-founded Magway in 2017 with his business partner, Rupert Cruise, who worked as an engineer on Elon Musk’s Hyperloop project. A pilot project was first developed using US$2.2 million raised via crowdfunding, before the UK government’s ‘Driving the Electric Revolution Challenge’ awarded the project a further US$2.6 million.

"Magway’s faster, safer, cheaper, and most importantly greener, than other alternatives," says Davies.

The initial infrastructure is focused on connecting a West London distribution centre with two large consolidation centres just outside the city, with the connection having the capacity to handle more than 600 million packages a year. There are also future plans to install 850 kilometres of track inside decommissioned gas pipelines that can provide consumers with direct service in the capital.

A key aspect of Magway’s approach is miniaturising the system. Carts transporting the goods will run inside the pipes that are only one metre in diameter. That said, the system is capable of handling 90% of packages sent.

Magway can utilise the pipe network to deliver large quantities of goods.

The system also offers a range of other benefits when compared with current approaches. There are no driver limitations, and the tunnel system offers a highly secure delivery method with no chance of road accidents. It can also operate efficiently at any time and in any weather, as well as offer accurate tracking of parcels along delivery routes.

Magway estimates that the cost savings can be greater than 70% when compared with road network alternatives.

How It All Works

Magway operates inside small diameter plastic pipes similar to those used for normal industrial and household purposes. It simplifies the creation of needed infrastructure, since existing methods and approaches to tunnelling and piping can be applied.

Using new or existing pipelines that can be underground or overground, Magway carts run close to one another at a speed of up to 50 km/hour. Automated loading and unloading is controlled by state-of-the-art technologies that keep the cart flow continuous in the system.

About Materials

"From the durability point of view, steel is basically the ultimate choice. In other words, we have a steel wheel on a steel track to ensure maximum strength of both the cart and the track chain. As for rails, we tried different materials. Aluminium doesn't last long. A steel rail, from the other side, is incredibly easy to work with: it bends easily, while remaining strong," says Bradley Smith, a Magway project engineer.

Foto: https://www.magway.com

Steel is also an important part of the linear motor that is built in the Magway track chain, with a seven kilogramme steel core in the coil with three copper windings. The coil is combined with silicon plates, which increase the natural speed and efficiency of steel when creating and maintaining magnetic fields.

The carts themselves are made from light plastic and have a steel wheelbase without a motor or a battery. Instead, they are put to motion by linear synchronous magnetic motors installed in the tracks. A set of powerful permanent magnets is attached to each cart. They are driven forward by magnetic waves that repel magnets in the carriage.

The magnetic wave of the electric current is powered straight from the grid, and absence of moving parts in the transmission line reduces operational and maintenance costs.

Although the company was established only three years ago, the Magway technology has undergone several modifications, including an early monorail model, which was eventually rejected in favour of a system with two rail guides. The idea behind this solution reflects the fundamental spirit of the Magway design, which uses proven technologies to implement an innovative system.

Bradley Smith is a Magway project engineer who recognises capacity and reliability as key elements. "From construction standpoint, our goal is to use known technologies to create something new," he says.

The unique electromagnetic properties of steel and its durability form the basis of the Magway system, and according to Smith, "there is nothing surprising that motors run 10 or 15 years."

Foto: https://www.magway.com

Magway estimates that the life of an installation will be a minimum of 50 to 80 years, with subsequent decommissioning and reworking of the design making it another area where steel can be the material of choice due to its unlimited recycling potential.

"Staying green relates to everything we do, and we always try to use the materials that can be recycled," says Smith.

Change the World for the Better

Magway is confident that is has a scalable solution to meet the growing needs of e-commerce. The technology on which it is based is proven and tested, the installations have a long service life and flexible maintenance requirements, and they can be easily integrated into existing systems.

Magway will continue to outscore not only conventional gasoline and diesel cars, but also electric cars, in terms of efficiency, since this technology does not rely on a battery.

The fact that the system is powered directly from the grid means that as renewable sources of energy increase their share in the global power generation, the impact of the system on the environment will only diminish.

Although Magway plans to expand in the UK first, Davies emphasises that "many of the problems we face here are common from sustainability standpoint. Environmental expenses, traffic jams, road maintenance and safety are global issues. We've been to Singapore, UAE, North America and Europe, and therefore, are confident that we can deliver and roll-out Magway on the international scale.”

With road congestion, cost and efficiency being keys to Magway’s attractiveness, environmental aspects will still be the determining factors for Davies. "Sustainability runs through everything we do," he says.

"Magway’s faster, safer, cheaper, and most importantly greener, than other alternatives. We think what we’re doing here is not just changing the game rules but rather changing the world."